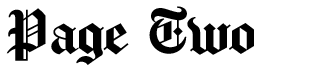

To truly comprehend the environmental implications of printer cartridges, it’s imperative to grasp the diverse array available in the market. The startling reality is that an estimated 375,000,000 cartridges find their way into U.S. landfills annually – equivalent to over a million cartridges per day or approximately 11 cartridges every second. These seemingly small items, often overlooked, carry a colossal environmental burden: printer cartridges can take up to a staggering 1000 years to decompose. Additionally, the production of a new toner cartridge demands roughly a gallon of oil, underscoring the hidden ecological costs tied to this ubiquitous technology.

The Dynamics of the Printer Cartridge Industry

The printer cartridge landscape, as reported by Bloomberg Businessweek, is a $35 billion arena characterized by the fierce competition among name-brand original equipment manufacturer (OEM) cartridges, remanufactured alternatives, and newly constructed single-use compatible cartridges sourced from overseas.

Name-brand cartridges, hailing from manufacturers like HP, Canon, and Epson, are often associated with higher costs, prompting individuals to explore economical alternatives.

Remanufactured cartridges, a pivotal component of the industry’s evolution, begin with recycled, cleansed, rebuilt, refilled, and rigorously tested OEM cartridges. Professionally executed remanufacturing ensures quality that either meets or surpasses that of name-brand counterparts.

In contrast, compatible cartridges represent newly fashioned, single-use options often referred to as ‘knock-offs’, ‘clones’, or ‘counterfeits’ of OEM printer cartridges. These cartridges, originating overseas, are constructed using either all-new components (as opposed to recycled materials) or haphazardly remanufactured parts.

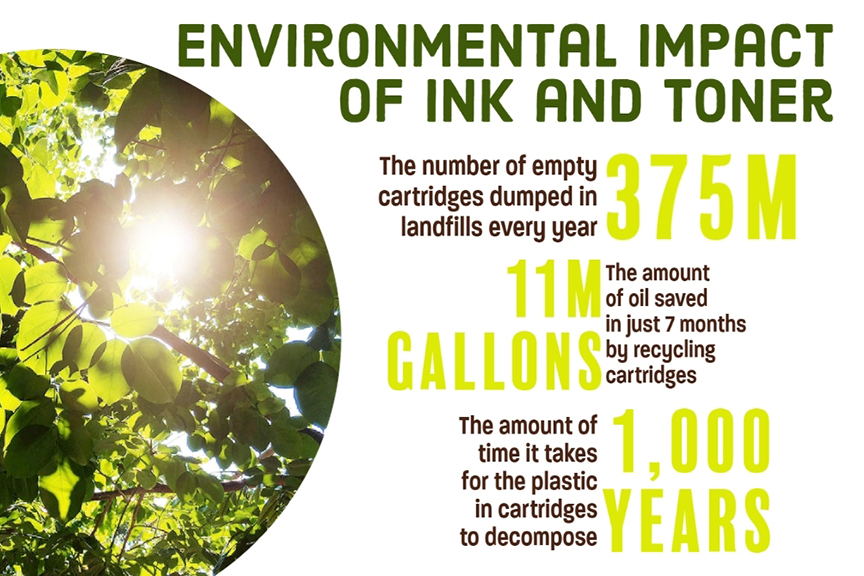

Considering Environmental Costs

Both remanufactured and compatible cartridges provide cost-effective alternatives to the pricey OEM counterparts. However, it’s essential to reckon with the environmental toll incurred by single-use compatible cartridges manufactured overseas.

Remarkably, each printer cartridge necessitates more than two ounces of oil during production. Consequently, this industry consumes a staggering 4,000,000 gallons of oil annually, further exacerbating environmental challenges.

The Issue of Plastic Waste

Single-use compatible cartridges from overseas pose an additional predicament – they lack recyclability. Consequently, they contribute to the mounting heap of plastic waste in landfills.

The Role of U.S. Cartridge Remanufacturing

The U.S. Cartridge Remanufacturing industry emerged as a solution within the expansive consumable printing market. Opting for U.S.-made remanufactured cartridges over newly constructed single-use compatibles from abroad holds the potential to dramatically reduce waste generation. This shift in consumer choice could significantly mitigate – if not eliminate – the burden imposed by single-use cartridges.

U.S.-made remanufactured printer cartridges offer a twofold advantage: they extend the life cycle of genuine OEM cartridges and come at a price tag that can be up to 50% less. These remanufactured cartridges emerge as the sole eco-friendly, recycled print consumables available.

For those seeking a budget-friendly alternative to branded OEM printer cartridges, the recommendation is clear: prioritize U.S. remanufactured cartridges over their single-use counterparts. By doing so, consumers not only save money but also contribute to a sustainable and responsible approach to printing technology.