In a perfect example of the circular economy in action, corn stover — stalks and leaves left over from harvest — becomes a valuable cash crop for which farmers can get paid.

Corn stands at the heart of the United States’ food system, serving as the country’s most valuable crop, generating approximately $75 billion in revenue annually. It holds the distinction of being the most widely planted crop, cultivated across approximately 90 million acres each year, an area roughly equivalent to the size of Montana. The United States is the world’s largest producer, consumer, and exporter of corn.

However, a surprising fact is that only 1 percent of this corn is the sweet variety enjoyed on dinner tables, while the remaining 99 percent is field corn. Unlike sweet corn, which is a vegetable harvested fresh in the summer, field corn is a grain harvested dry in the fall, primarily used for feeding livestock (cattle, hogs, and chickens) and making fuel ethanol. The remainder is processed into various products such as starch, sweeteners, corn oil, and beverages for human consumption.

After the fall harvest, farmers are left with what is known as “corn stover” — the residue of stalks and leaves. Traditionally, it is left on the field and tilled back into the soil when it’s time for re-seeding. However, as US corn output continues to rise, with a projected 11 percent increase this year, many farmers are finding themselves overwhelmed with an excess of corn stover.

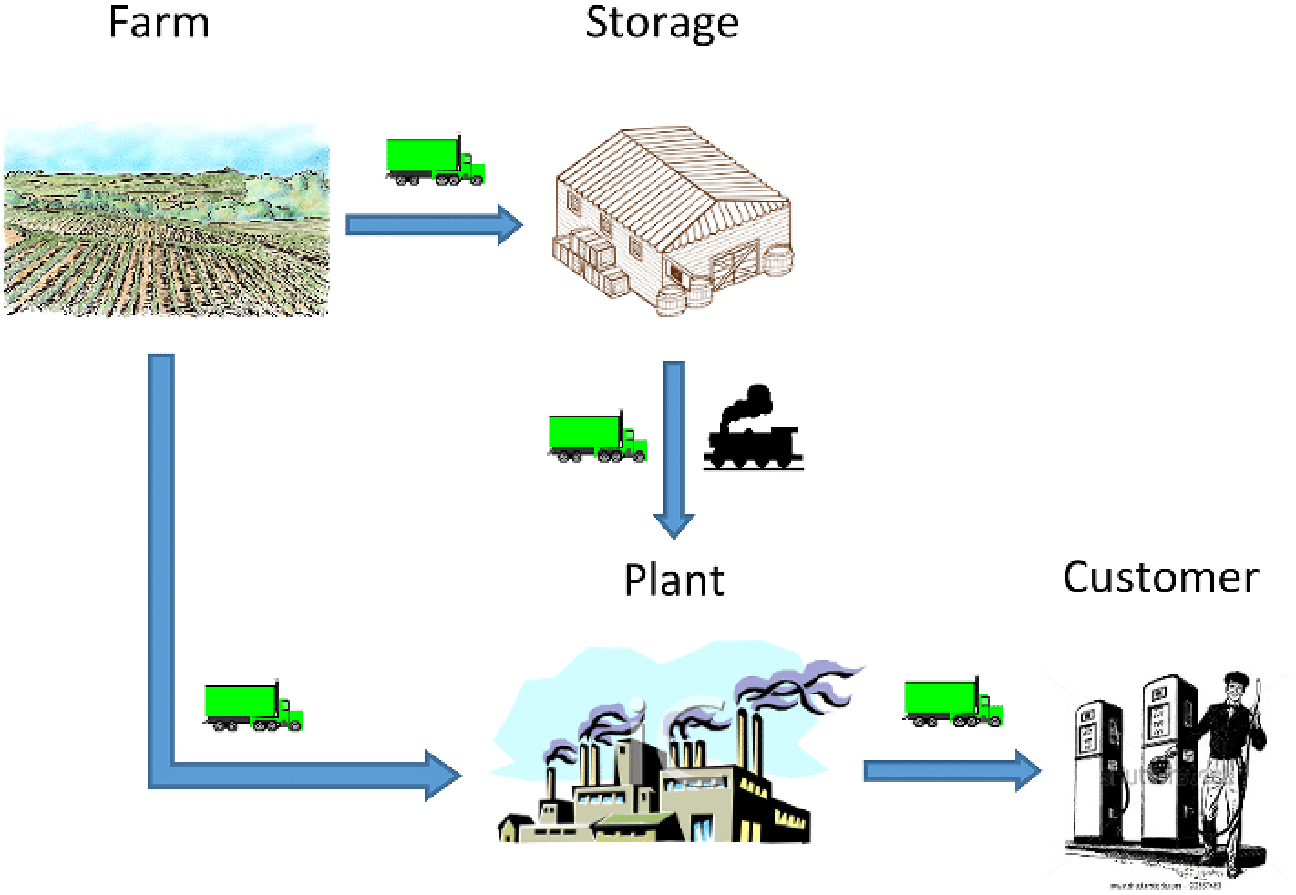

New Energy Blue has developed a groundbreaking process for transforming corn stover into biobased ethylene. The company purchases agricultural residue from farmers, carefully leaving the bottom half of the stalks on the field to replenish the soil. The top half is baled as feedstock for conversion into ethanol at New Energy Biomass Refinery operations being developed in the US heartland. Almost half of the ethanol produced is then processed into plant-based ethylene — the hydrocarbon gas widely used in plastic production.

This transformation of corn stover into biobased ethylene is a prime example of the circular economy in action. Corn stover, which was previously considered waste, has now become a valuable cash crop for farmers, creating a new revenue stream. According to Thomas Corle, CEO and Chairman of New Energy Blue, this additional income is especially welcome given the fluctuating price of corn grain.

To effectively scale up the processing, New Energy Blue has partnered with Dow, signing a long-term supply agreement in North America. Dow will purchase the biobased ethylene and utilize it in recyclable applications across packaging, transportation, and footwear.

Dow’s Global Sustainability Director for Olefins, Aromatics & Alternatives, Manav Lahoti, emphasized that Dow is supporting this sustainable commercial production because investing in innovation is the best way to find new solutions. Dow’s agreement with New Energy Blue not only allows for scaling up production but also ensures a value-added end market for the diversion of agricultural residues.

The carbon cycle plays a significant role in this innovative process. Corn plants absorb carbon dioxide as they grow, while corn stover releases some of it into the atmosphere as it decomposes on the field after harvest. By repurposing this otherwise wasted carbon, New Energy Blue’s innovation helps reduce greenhouse gas emissions from the agricultural sector.

This collaboration will bring forth a new processing facility known as New Energy Freedom in Mason City, Iowa, set to open in 2025. It will process 275,000 tons of corn stover every year, producing commercial-scale quantities of second-generation ethanol and clean lignin. Approximately half of the ethanol will be converted into biobased ethylene feedstock for Dow products. Given that Iowa and Illinois account for about a third of the corn grown in the US, this location is ideal for this endeavor.

Thomas Corle emphasized the versatility of their biomass refinery, stating that it can create bio-feedstock for a wide range of products, from textiles and plastics to jet fuel. Dow’s ability to use a renewable carbon feedstock for manufacturing biobased plastics significantly reduces the overall carbon footprint of these products.

Manav Lahoti believes that this collaboration will redefine how Dow sources carbon-based feedstocks, expanding options for ethylene to include renewable resources. It opens the door to lower carbon footprint applications across various sectors, including transportation, cosmetics packaging, consumer products like shoes, and food packaging, delivering fresh and reliable products across the country.

New Energy Blue’s innovative technology not only benefits farmers and businesses but also ushers in a more sustainable future for US agriculture. It exemplifies the power of a circular economy, turning what was once considered waste into a valuable resource and contributing to a greener, more environmentally responsible future. With the potential to expand the use of corn stover as feedstock for biobased plastic and other renewable applications, this innovation offers a promising step towards a more sustainable and circular economy.