In an era when sustainability is taking center stage, the airline industry is soaring toward a greener horizon. As concerns about the environmental impact of air travel grow louder, aviation is responding with a resolute commitment to achieving Net Zero emissions by 2050. This journey towards sustainability is paved with various strategies, ranging from investing in fuel-efficient aircraft to embracing innovative propulsion systems, but one often-overlooked hero in this quest is the aircraft interior.

Reducing Weight for a Sustainable Future

While airlines are exploring multiple avenues to sustainability, one strategy has proven to be a cost-effective and environmentally friendly solution: reducing weight. Lightweight aircraft interiors, comprising about 10% of an aircraft’s empty weight, significantly cut fuel consumption and greenhouse gas emissions. However, the benefits go beyond the reduction in fuel costs and emissions, as they also lead to operational savings by requiring less cleaning, fewer spare parts, and fewer repairs.

Furthermore, airlines are now considering the full lifecycle impact of cabin interiors. Given that cabin interiors are replaced four to five times during an aircraft’s life, it’s crucial to ensure that the manufacturing and disposal of these interiors align with sustainability goals.

The Environmental Impact of Air Travel

To understand the urgency of sustainability in aviation, we must first grasp the environmental toll it exacts. A study by the European Parliament revealed that aviation was responsible for 3.8% of the EU’s total greenhouse gas emissions in 2019, making it the fastest-growing source of emissions since 1990. With global airline traffic continuing to surge, the pressure on the industry to address these concerns is intensifying.

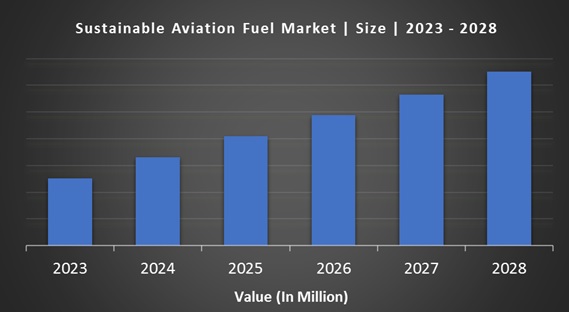

The Need for Sustainable Aviation Fuel (SAF)

Airlines are taking significant steps to reduce their environmental footprint, such as American Airlines’ commitment to purchase 100 million gallons of Sustainable Aviation Fuel (SAF) annually by 2027. The International Air Transport Association (IATA) reported that global SAF production tripled between 2021 and 2022. Despite its higher cost compared to conventional fuel, SAF is gaining traction, with half a million commercial flights already operated using this sustainable alternative.

However, SAF alone cannot fully address the industry’s sustainability challenges. The University of California, Irvine, estimates that meeting aviation’s fuel needs with biofuels would require vast amounts of land. Even if SAF entirely replaced petroleum-based fuels, it would only contribute around 65% of the emissions reduction required to achieve net-zero emissions by 2050.

This brings us back to the significance of aircraft interiors in the sustainability equation. While investing in new aircraft can reduce emissions substantially, lightweight interiors offer a high return on investment with minimal risks or downsides. For instance, lighter seats and other weight-reduction practices can generate fuel savings between 0.65% and 0.85%, resulting in billions of dollars in savings for airlines.

Moreover, cabins have unique marketing value, as they are the only part of the aircraft directly engaged with by passengers. Airlines are increasingly leveraging sustainable interiors to align with customers’ environmental expectations and boost their public image.

Sustainability in aircraft interiors also helps alleviate concerns about the environmental impact of premium seating. First-class and business-class cabins, while profitable for airlines, can emit significantly more CO2 per kilometer than economy class. Sustainable interior designs can mitigate this impact and contribute to a more eco-friendly image for airlines.

Substantial Fuel Savings and Emission Reductions

Some innovative products exemplify how aircraft interiors contribute to sustainability – including new seat technology. They produce seats that are not only lighter but also more durable and comfortable. Replacing older-style business-class seats with these lightweight options can result in substantial fuel savings, contributing to the industry’s emission reduction goals.

The sustainability of aircraft interiors goes beyond operational efficiencies, extending to manufacturing and disposal processes. Airlines are increasingly seeking solutions that align with their sustainability strategies throughout a product’s lifecycle. Utilizing eco-friendly manufacturing processes and recyclable materials are essential components of this effort.

The airline industry is undergoing a transformative journey toward sustainability, with aircraft interiors playing a crucial role. By choosing lightweight and eco-friendly interior options, airlines can achieve significant fuel savings, reduce emissions, and align with the expectations of environmentally conscious passengers. This commitment to sustainability is not only good for the planet but also for the industry’s long-term viability and profitability. As we take to the skies, the inside story of sustainability is becoming an integral part of the airline industry’s narrative, promising a greener future for all.