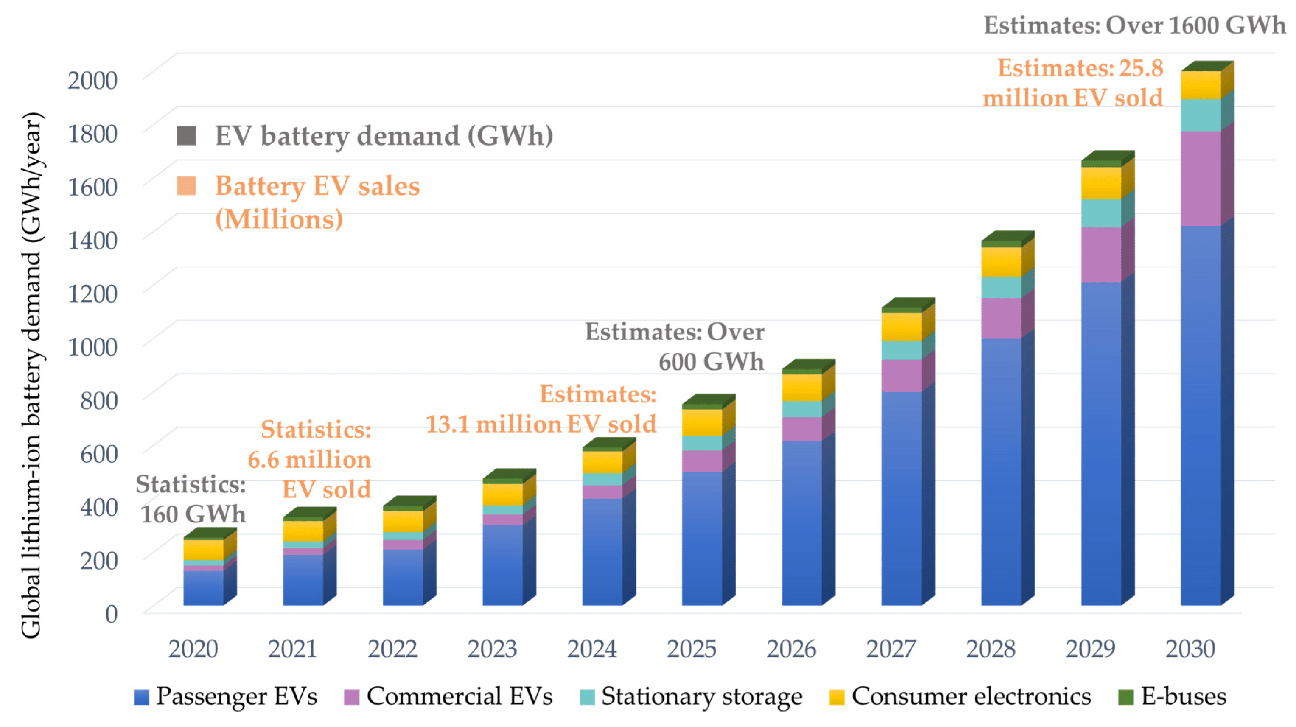

The landscape of electric vehicles (EVs) is evolving at an unprecedented pace, with a surge in demand reshaping not only the automotive industry but also the intricate web of the electric vehicle battery supply chain. As Americans increasingly opt for environmentally friendly EVs, a critical spotlight is now on the ethical and sustainable challenges inherent in crafting the batteries that power these green machines.

Over the past two decades, the EV battery supply chain has undergone significant growth, but the next 20 years demand fundamental changes. With the demand for EVs soaring, key players in the industry, from auto manufacturers to battery creators, are finding themselves under the discerning eye of the American consumer. Issues like semiconductor supply chains, carbon footprints in manufacturing, and the crucial concept of circularity are now central to the conversation surrounding sustainable EV batteries.

Skyrocketing gas prices are propelling more Americans toward the electric revolution, prompting automakers to swiftly produce EVs to meet the growing demand. While the costs of EVs have decreased with technological advancements, tax credits, and improved battery technology, the short-term challenge lies in the rising costs of building EVs. The demand for essential materials is escalating, and the supply chain is under strain. In the face of these challenges, it’s tempting for industry players to cut corners for immediate gains at the expense of sustainable material sourcing. However, this is a perilous misstep that the industry cannot afford as consumers increasingly prioritize innovative and sustainable products, with EVs being no exception.

Historically, consumer concerns regarding EVs centered around cost, battery range, and charging speed of an electric vehicle battery. Addressing these concerns has been the industry’s focal point. However, as EVs become ubiquitous, the conversation is shifting toward the end of life for these vehicles. Safely disposing of and, crucially, recycling EVs are emerging challenges that demand innovative solutions. Automakers, material manufacturers, and consumers all play a vital role in responsibly managing resources and fostering innovation to propel America toward sustainable growth in the green transportation sector.

Thankfully, researchers are already delving into solutions. Cornell University, in collaboration with the National Science Foundation, is exploring ways to repurpose old EV batteries into storage units for renewable energy. This not only reduces the carbon footprint but also addresses the burgeoning energy storage crisis on the nation’s electric grids. Companies like Tesla are partnering with entities such as Redwood Materials to recycle waste and scrap battery material, while new EV battery technologies are in development to ease recyclability and reduce reliance on rare metals.

Considering the weight of EV batteries and their impact on energy needs, several auto manufacturers are teaming up with materials solutions providers to integrate advanced thermoplastic composites, lowering the weight of these units in the car’s body. Innovations like Ford’s F-150 Lightning, which integrates the battery into the body, further reduce weight and enhance efficiency.

At Solvay, a leader in battery and hydrogen growth platforms, efforts are underway to support research on circularity, contributing to a deeper understanding of how sustainable supply chains can drive decarbonization.

The journey toward a sustainable EV ecosystem requires a multifaceted approach. Governments, automakers, and materials providers must collaborate to ensure that the EV revolution lives up to its green promise. As we navigate this evolving terrain, it’s not just about powering vehicles; it’s about energizing a sustainable future for generations to come.