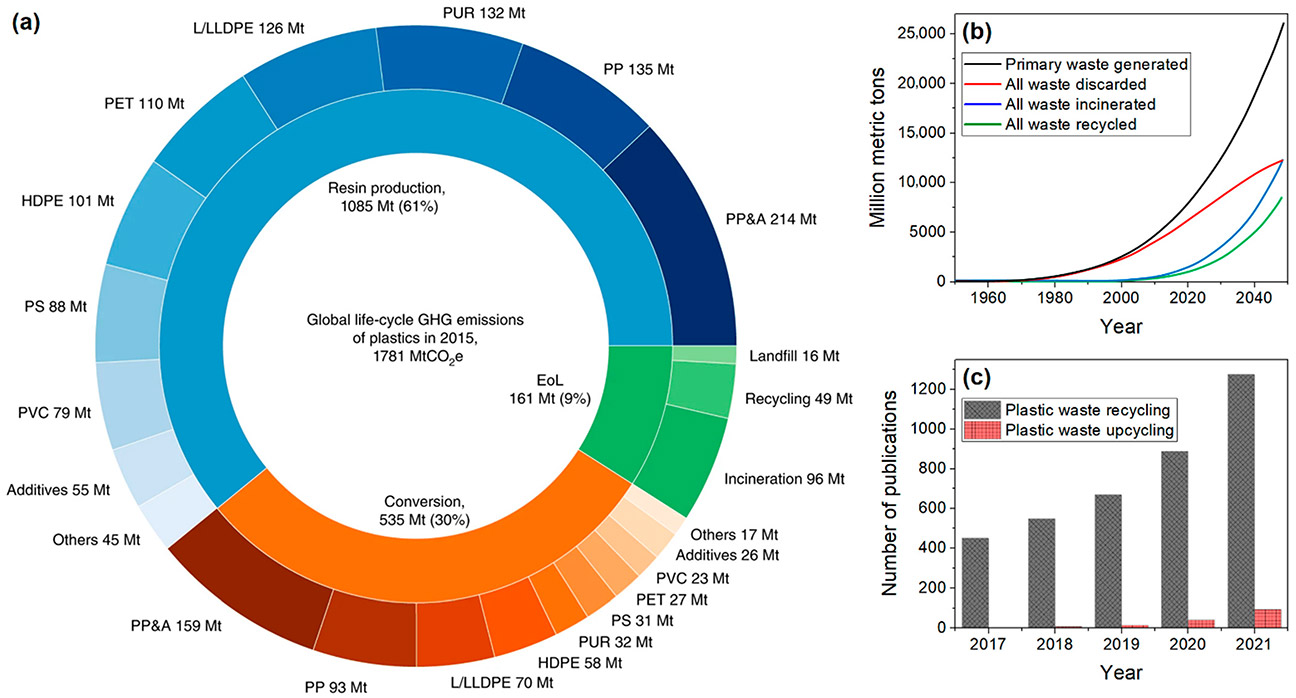

Plastic pollution is a global environmental crisis, with a significant portion of it attributed to discarded polyethylene (PE) products. Most PE items are disposed of after a single use, contributing to landfills and environmental degradation. Two forward-thinking chemical engineering faculty researchers at UMass Lowell, Associate Professor Dongming Xie and Hsi-Wu Wong, are tackling this issue head-on. With the support of a three-year, $463,000 grant from the National Science Foundation, they are developing groundbreaking technology to upcycle waste PE, aiming to contribute to a circular economy for plastics.

Waste PE constitutes over 50% of the world’s plastics waste stream, posing a major environmental concern. Associate Professor Dongming Xie, the principal investigator of the project, emphasizes the urgency of addressing this issue, especially given PE’s projected annual manufacturing growth rate of 12%. The lack of effective recycling options further exacerbates the environmental impact, highlighting the need for innovative solutions.

Xie and Wong identify shortcomings in existing PE recycling methods, including mechanical shredding, thermochemical treatment, and biochemical conversion. These methods result in low product qualities, inefficient conversion rates, and high processing costs. Recognizing these limitations, the researchers are committed to developing an alternative approach that aligns with the principles of a circular economy.

The concept of a circular economy is gaining traction as a sustainable solution to the linear use-and-discard model. In a circular economy, plastics continuously circulate in a “closed loop,” retaining their value through repeated reuse, repair, and recycling. The goal is to minimize waste and environmental impact, with materials being discarded only as a last resort.

Xie and Wong’s approach involves a two-step hybrid method to upcycle waste PE. First, they employ a thermochemical process known as oxidative catalytic pyrolysis to break down waste PE into intermediate molecules under high temperatures. These molecules, including alkanes, alkenes, aldehydes, and alcohols, are then subjected to a biomanufacturing process using a safe, genetically engineered yeast strain. This process converts the molecules into value-added products crucial to various industries, such as long-chain diacids for new nylon polymers and platform chemicals used in manufacturing polymer plasticizers, adhesives, emulsifiers, fungicides, and biopharmaceuticals.

Hsi-Wu Wong estimates that nearly 100 million tons of greenhouse gases are emitted annually from waste PE, underscoring the urgent need for sustainable solutions. If successful, the researchers believe that their innovative technology could potentially upcycle 10% of this waste, saving the planet 10 million tons of greenhouse gases each year.

The research not only addresses environmental concerns but also holds the potential to revolutionize manufacturing processes. The new chemicals derived from waste PE could offer competitive advantages over similar products produced with petroleum-based raw materials and potentially hazardous pathogen strains in other countries.

The work of Professors Dongming Xie and Hsi-Wu Wong represents a crucial step towards a more sustainable future. Their innovative hybrid approach to upcycling waste PE has the potential to significantly reduce environmental impact, contribute to a circular economy for plastics, and pave the way for the future manufacturing of essential chemicals from waste plastics. As the researchers continue their groundbreaking work, the hope is that their efforts will inspire further advancements in sustainable technologies, creating a cleaner and greener world for future generations.